Product Description

Downpipe roll forming machine steel pipe production line

Downpipe roll forming machine steel pipe production line is composed of uncoiler, the feed leading table, the main machine, the formation cutting device, hydraulic system, control system and the product bracket.

Main features of Steel downpipe production line

In order to offer a complete gutter system --- and do it all "in-house" --- you need Downspout Pipe Roll Forming Machine has following advantages:

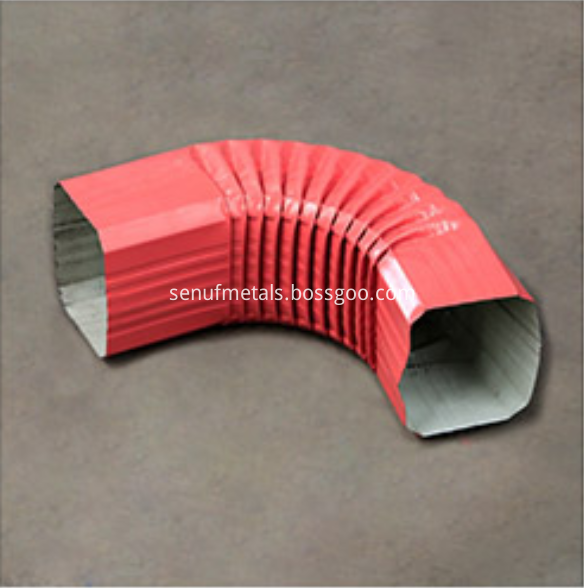

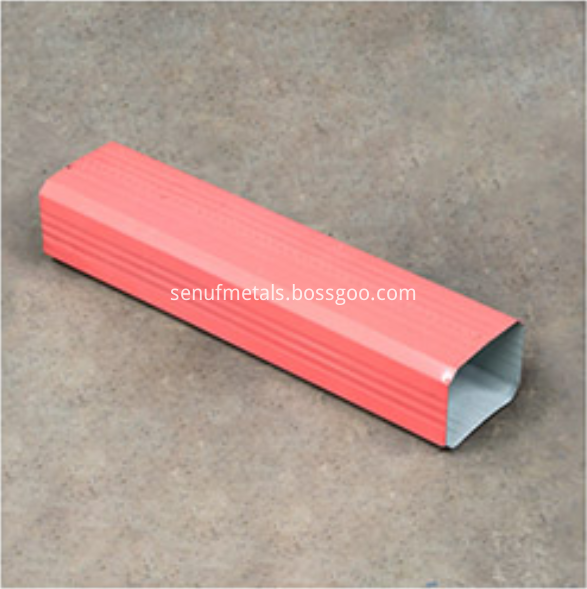

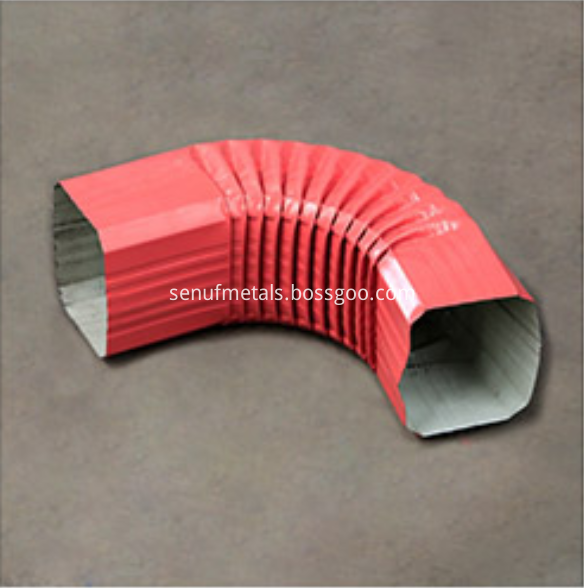

1. Make both downspout pipe and elbows(with bending device for engineering convenience)

2. With square type downspout pipe nd round type downspout pipe for optional

3. Easy operation, low maintenance cost

4. Stable and efficient

Detailed Images of Downpipe roll forming machine steel pipe production line

Machine Parts

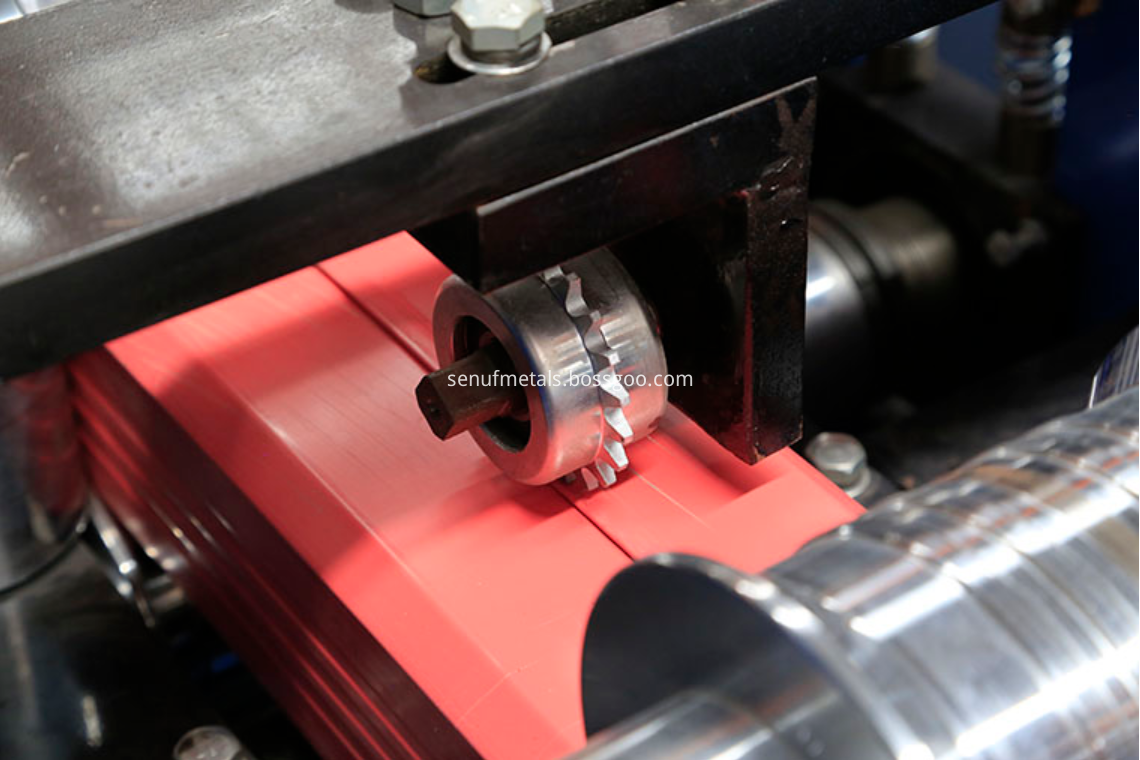

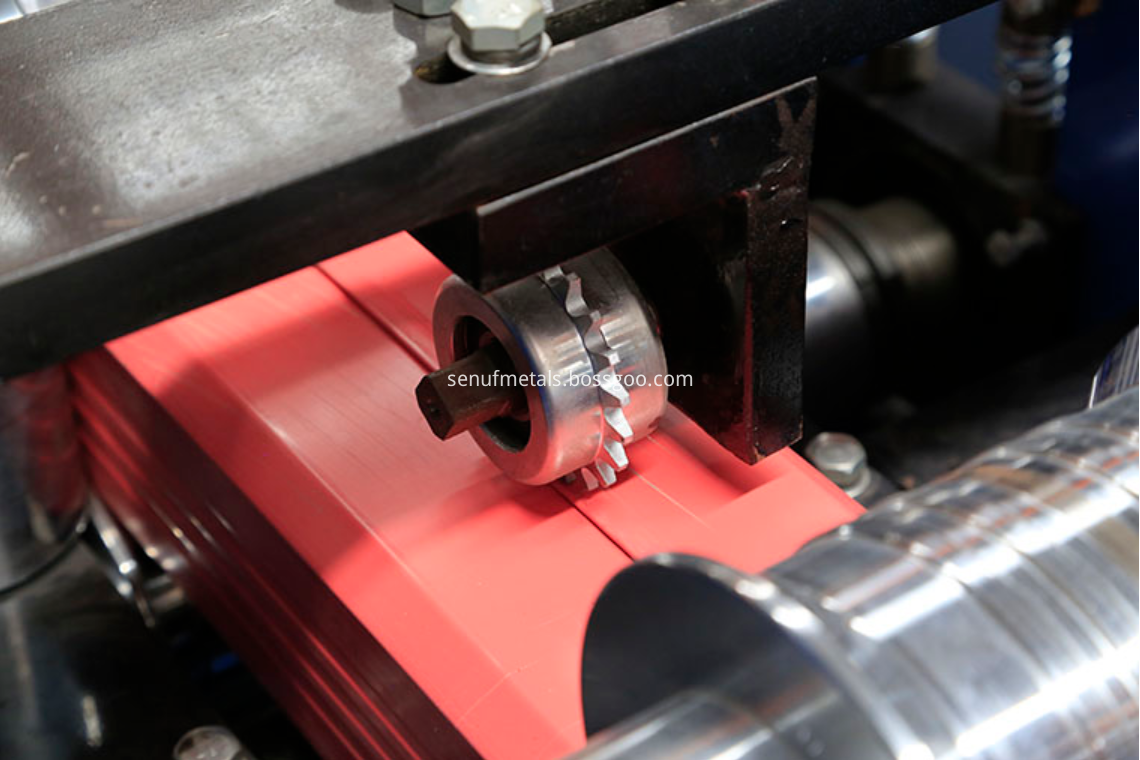

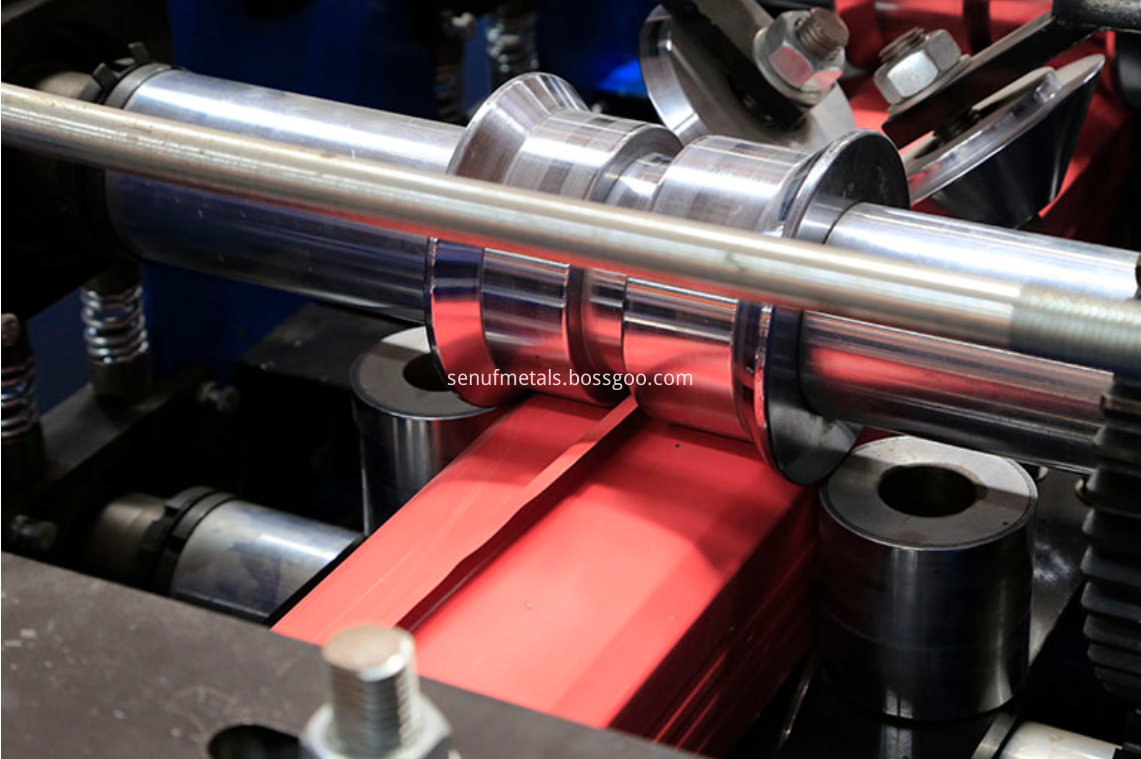

1. Steel downpipe production line tooth shape making device

Brand: SUF, Original: China

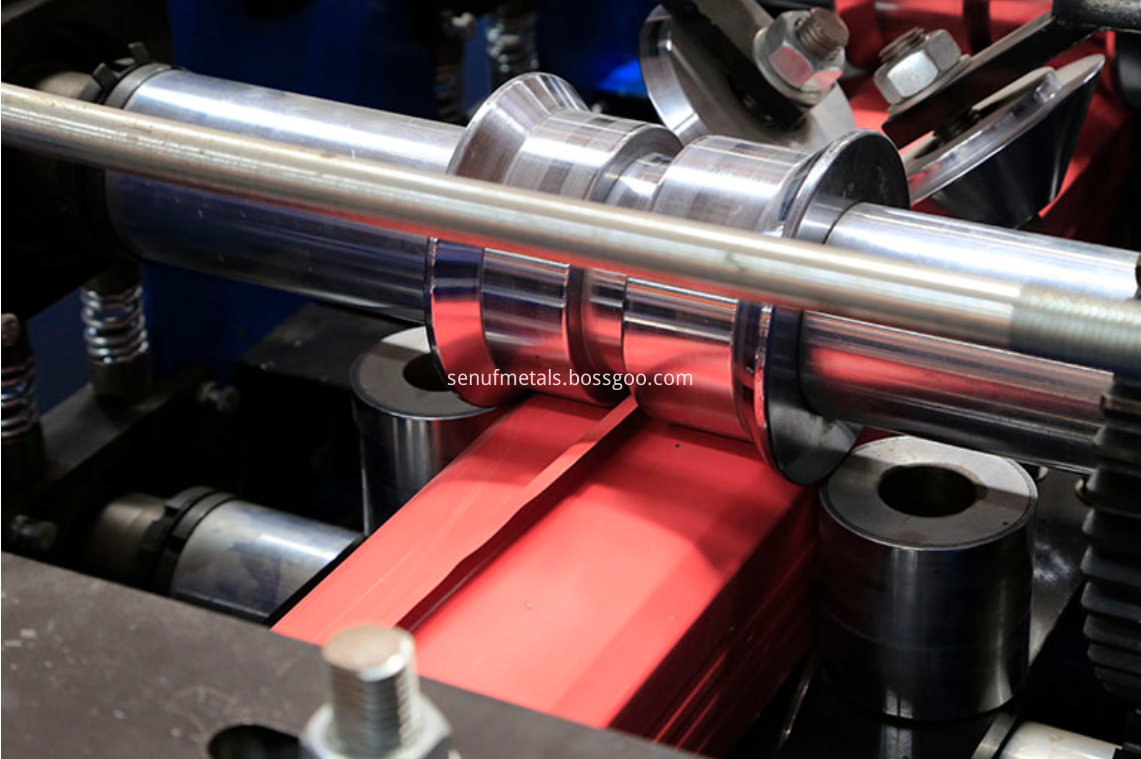

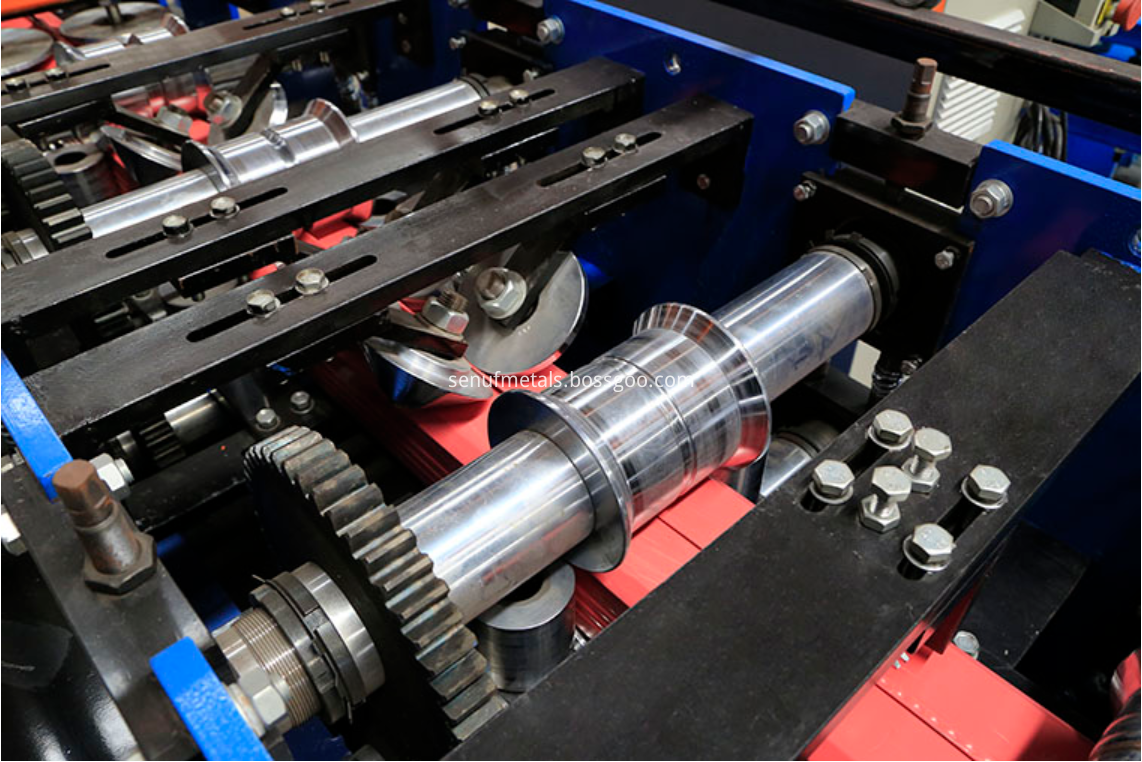

2. Downpipe roll forming machine steel pipe production line rollers

Rollers manufactured from high quality steel 45#, CNC lathes, Hard-Chrome Coating for options.

With feeding material guide, body frame ade by 450H type steel by welding

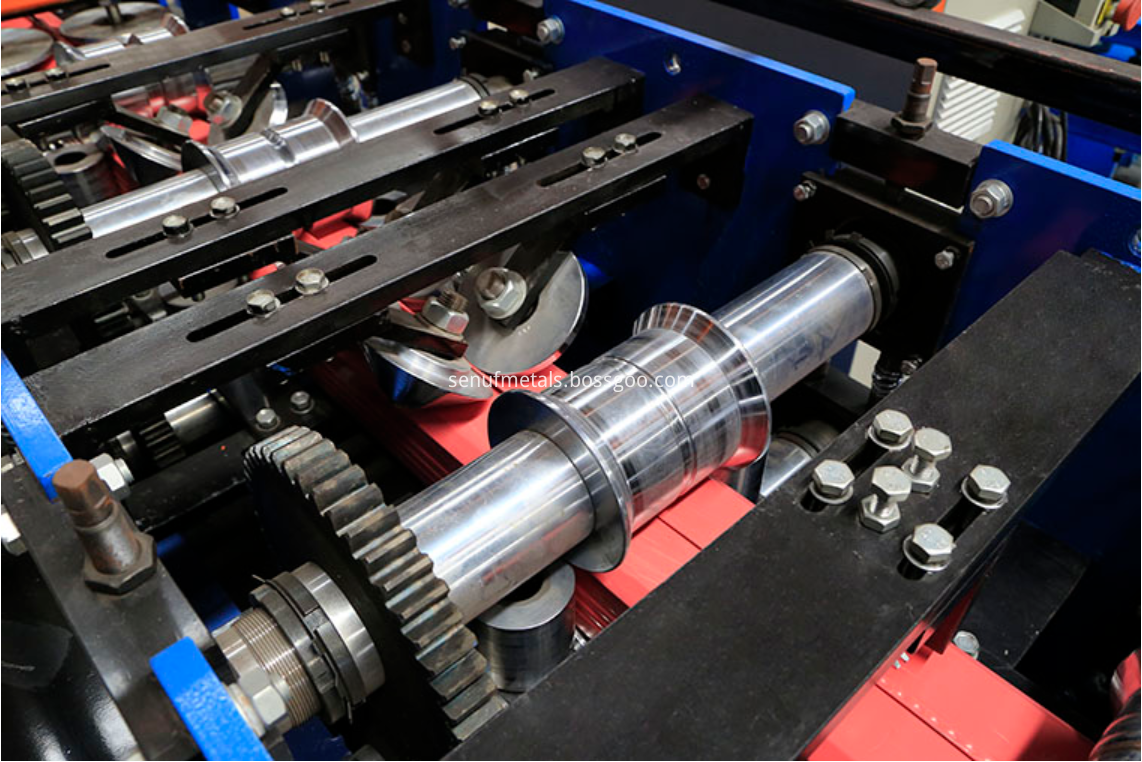

3. Downpipe roll forming machine steel pipe production line cutter

Made by high quality mold steel Cr12 with eat treatment,

Cutter frame made by high quality 20mm steel plate by welding

Hydraulic motor: 4kw, hydraulic pressure range: 0-16Mpa

4. Downpipe roll forming machine steel pipe production line bender

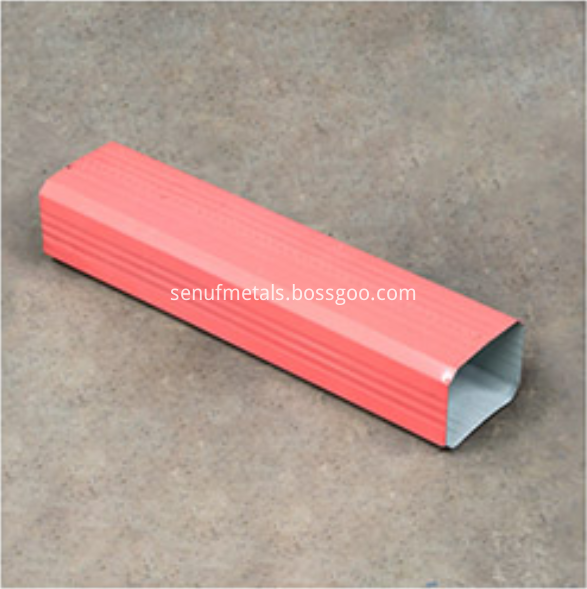

5. Downpipe roll forming machine steel pipe production line samples

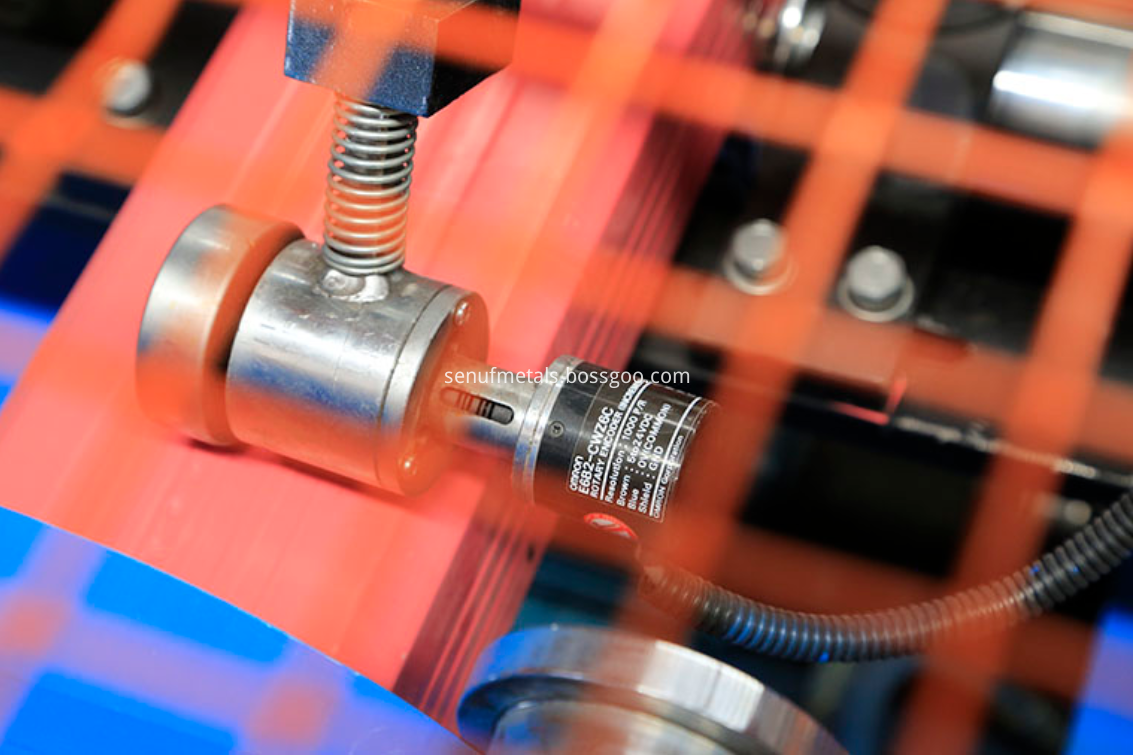

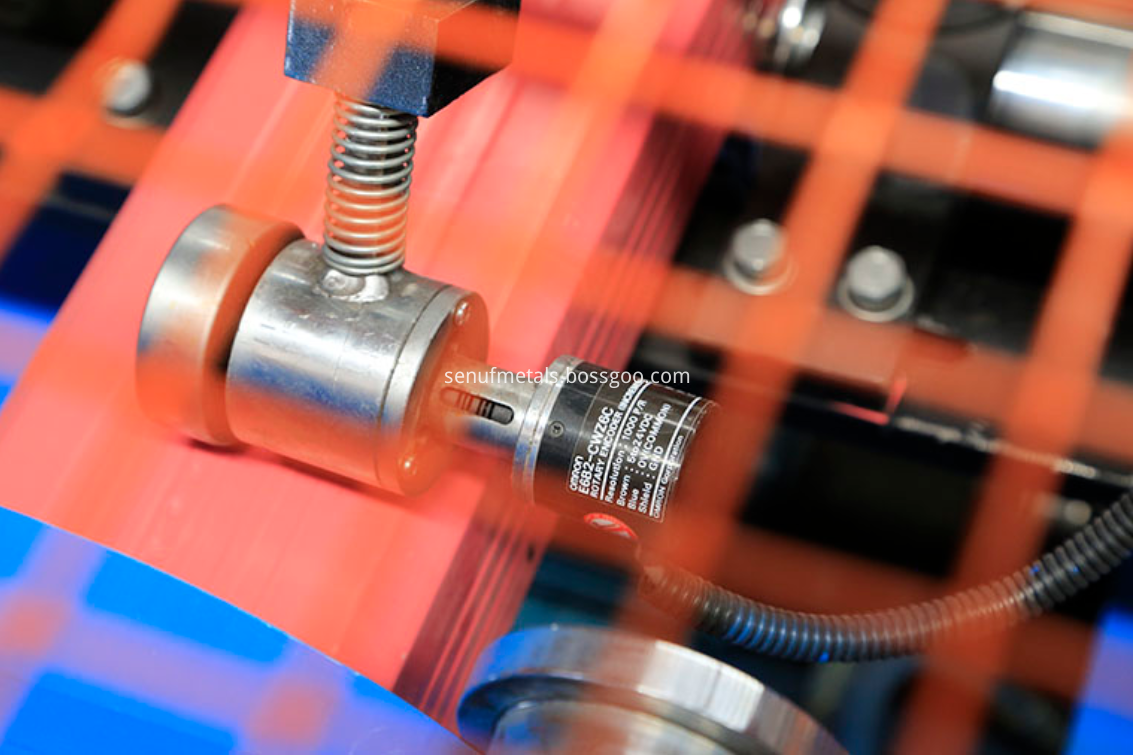

6. Downpipe roll forming machine steel pipe production line PLC control system

PLC control system (Touch screen brand: German Schneider Electric/Taiwan WEINVIEW, Inverter brand: Finlan VOCAN/Taiwan Delta/Alpha, Encoder brand: Omron)

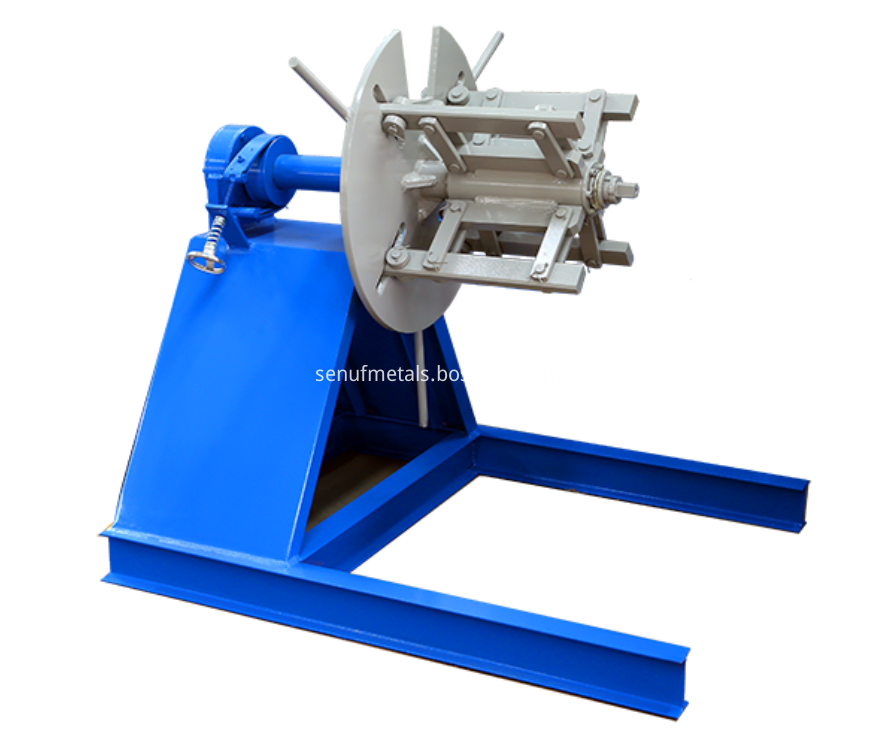

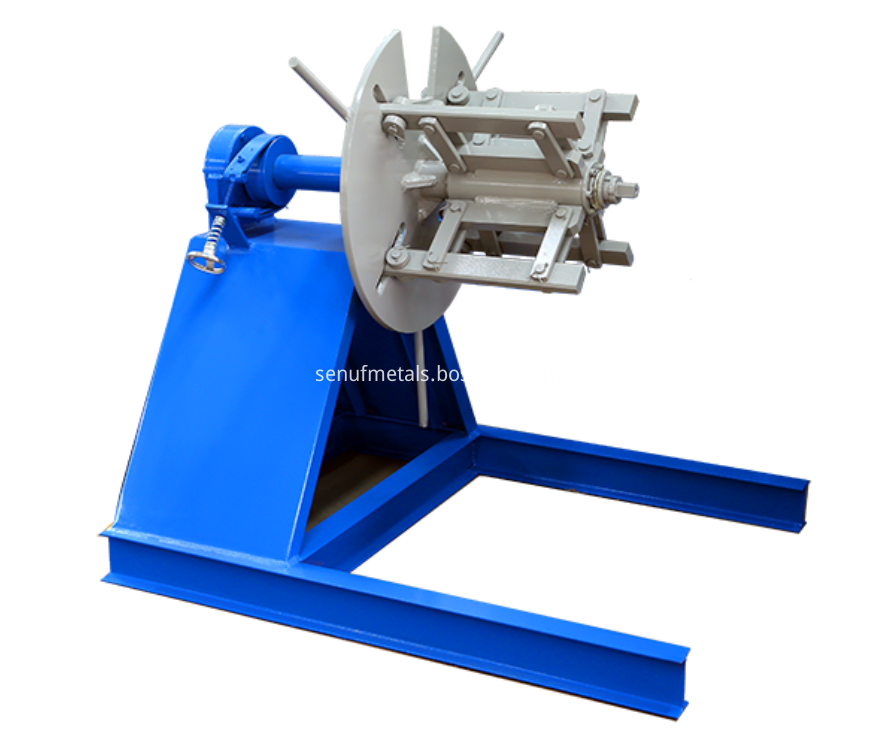

7. Downpipe roll forming machine steel pipe production line Decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore Shrinkage nd stop

Max. feeding width: 500mm, coil ID range 508±30mm

Capacity: Max 3 ton

With 3 tons hydraulic decoiler for option

8. Downpipe roll forming machine steel pipe production line exit rack

Un-powered, one unit

Contact info: WhtasApp: +8615716889085

.png) Contact Now

Contact Now