Product Description

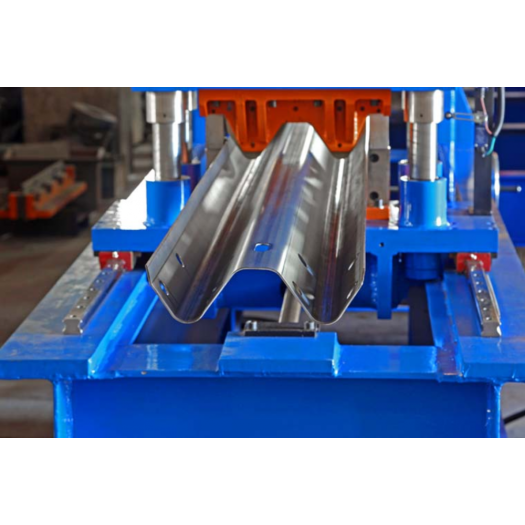

Highway guardrail roll forming machine

The Highway guardrail roll forming machine is the special forming equipment for producing the speedway guide rail. The machine adopts the cold forming, cold punching, automatic stack, industrial automation controlling system and precision machining technology, therefore is can run full automatically, including decoiling, forming, cutting to length and stacking. One shift every month can produce 600 tons (max).

Main features of highway guardrail roll forming machine

The advantages of Two waves highway guardrail forming machine are as follows:

1. Beautiful appearance,

2. Accuracy profile,

3. Easy operation, low maintenance cost

Detailed images of Highway guardrail roll forming machine

Machine parts

1. Highway guardrail roll forming machine feeding and leveling

Feeding motor: 11kw, servo motor

With connecion platform

Acoiling tail and a roll of material is easy to set welding platform

Welding machine is provided by the buyer

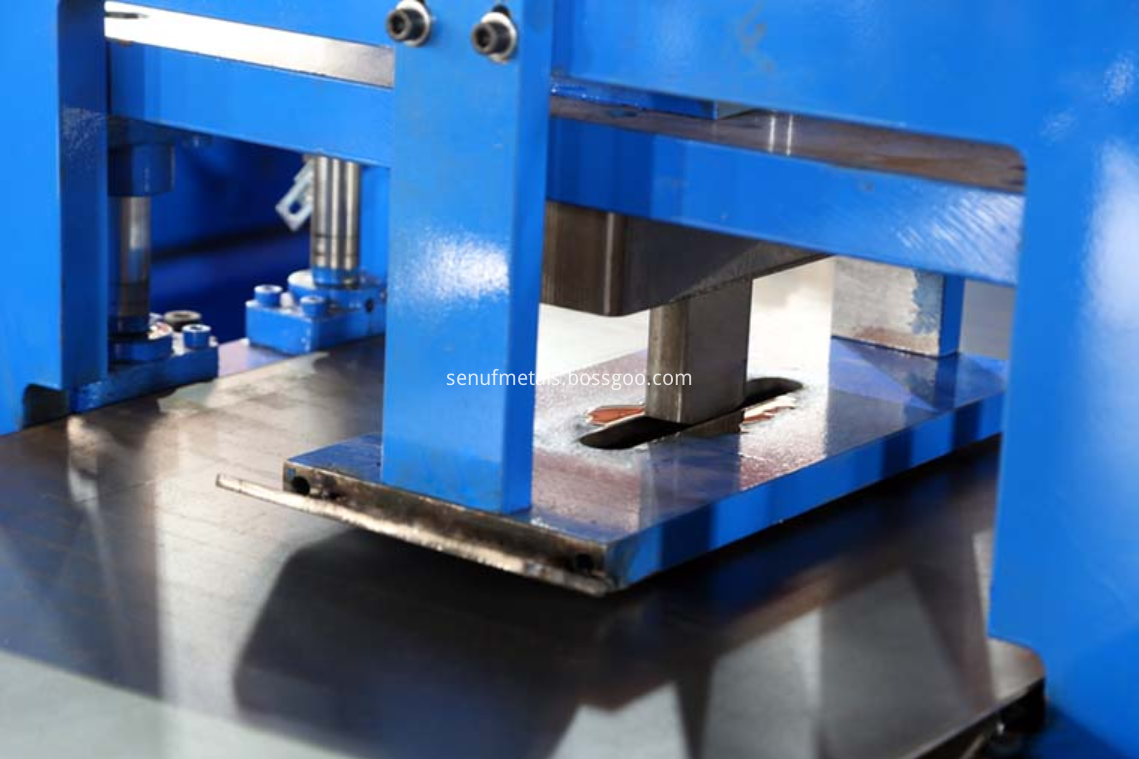

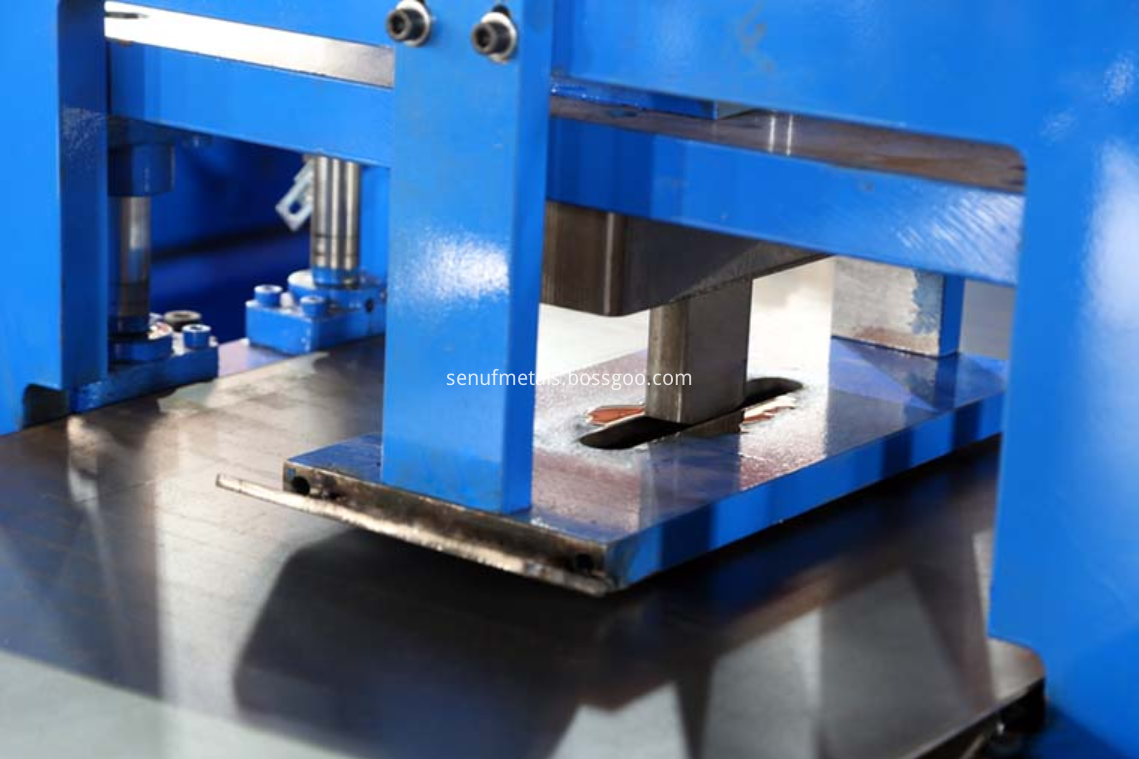

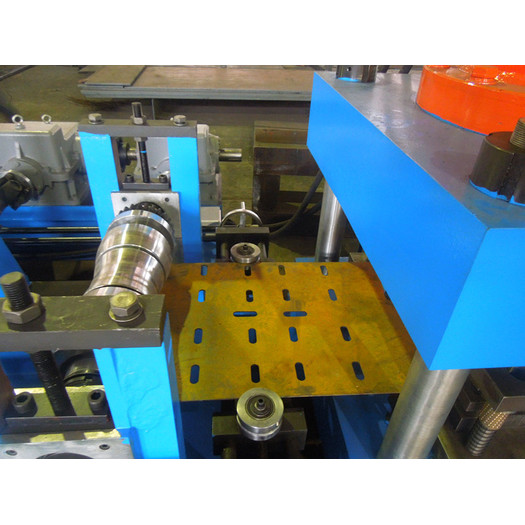

2. Highway guardrail roll forming machine hydraulic pre-punch device

The main oil press (200 tons), two sets of punch mold, changing different die for different mold,

Two sets of punching mold, the material of punching die: Cr12mov, hygraulic: 22kw

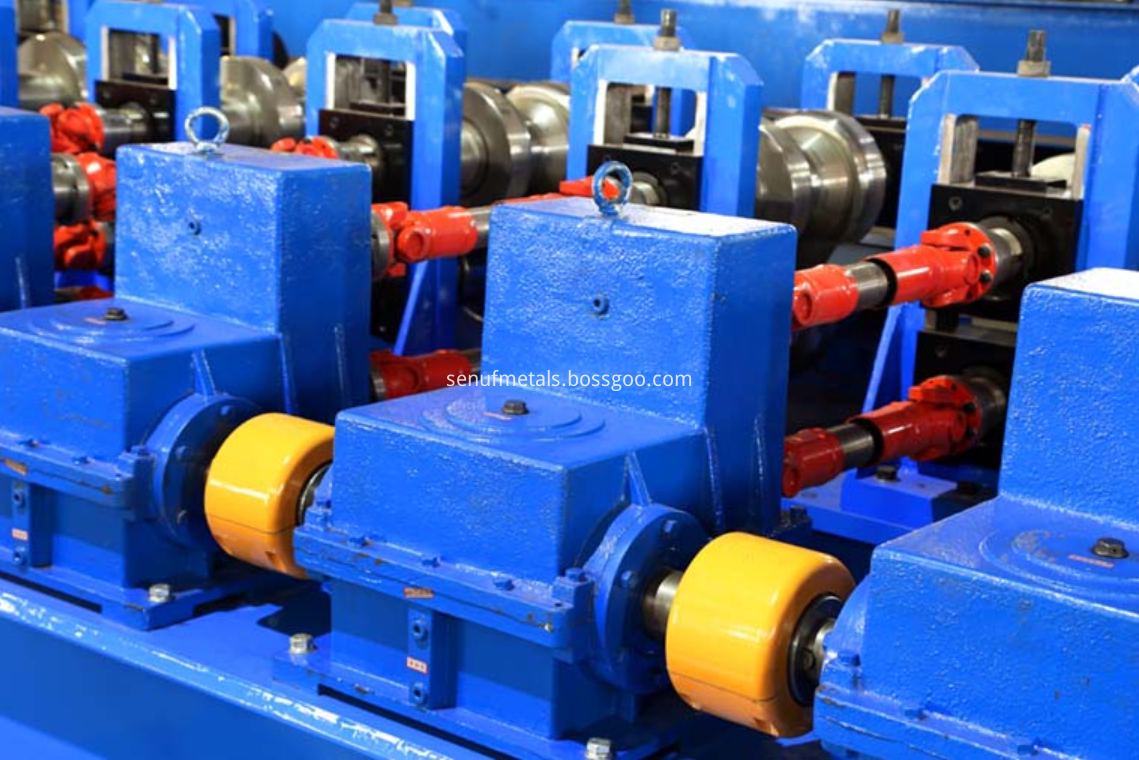

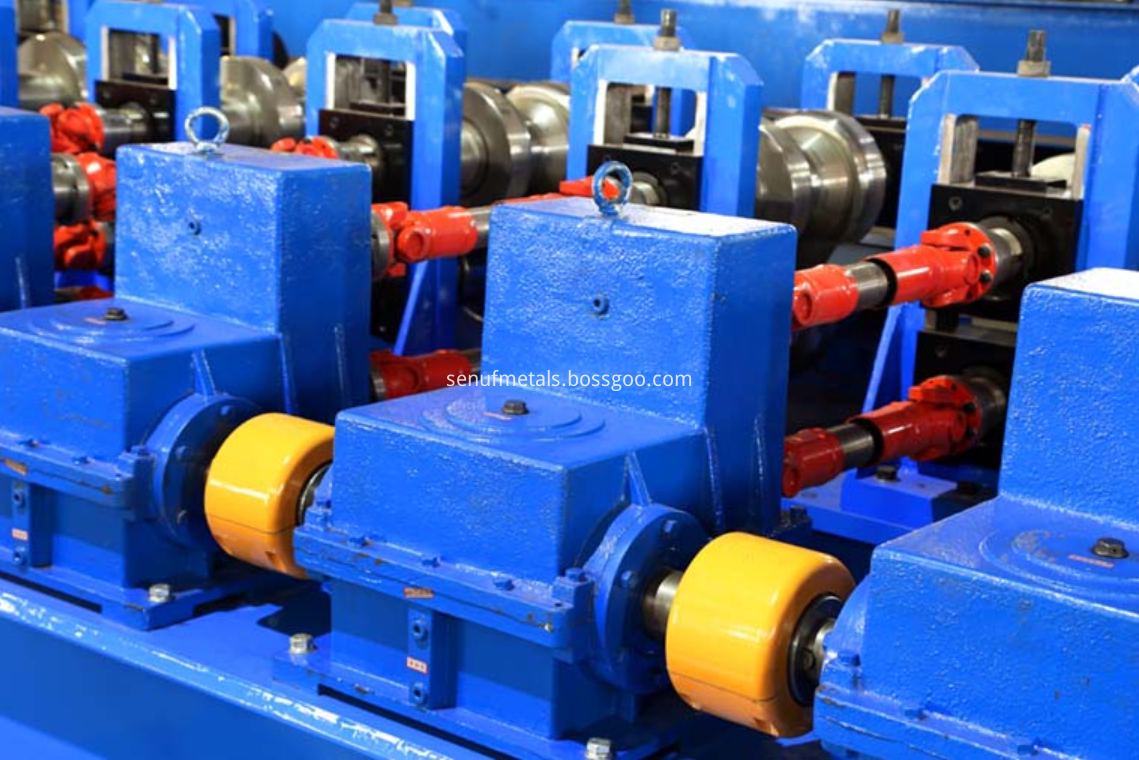

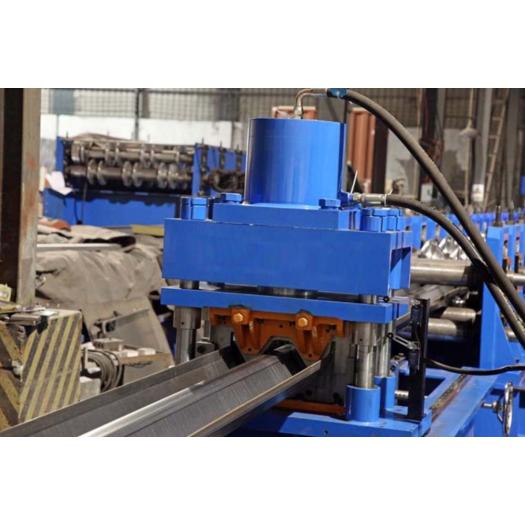

3. Main highway guardrail roll forming machine

Gear box drive(upper and lower rollers with power), column typw structure design,

18 steps to form, designing 16 steps and keep 2 step for spare use,

Rollers manufactured by Cr12mov(SKD11), precision machined,

Rack using 45# wage steel seal plate, the overall processing,

Main motor 45kw, frequency speed control,

Forming speed: 1 pcs per minute based on 4320mm length

45kw powerful motor

Gear box driving

4. Highway guardrail roll forming machine post cutter

When producing different length profiles, adjust the distance between the cutting and punching,

To achieve a stop, once the completion of punching and cutting action,

Stop to cutting, no blanking cutting,

Hydraulic group: 22kw, independent hydraulic station,

Cutting tool material: Cr12mov

5. Highway guardrail roll forming machine decoiler

Hydraulic system expand coil inner hole, pump motor: 4kw,

Frequency inverter to regulate turning speed, motor: 2.2kw,

Coil inner diameter: 518±30mm, coil outer diamter: 1600mm,

Load capacity: Max 10 tons, coil width: Max 600mm

Pneumatic arm, air apply by the buyer

6. Highway guardrail roll forming machine exit rack

Un-powered, one unit, 5.5 meters long

Other details of Highway guardrail roll forming machine

Suitable for material with thickness 2.7-3.4mm,

Shafts manufactured by 45#, main shaft diameter 105mm, precision machined,

Motor driving, gear chain transmission, 16 rollers to form and 4 rollers for straightening and leveling,

Main motor 18.5kw, frequency speed control, forming speed approx 18m/min

.png) Contact Now

Contact Now